FD330TFC Paper bag with twisted rope flat rope and colors online High-performance machine is a latest design for square bottom box paper bags with flat handles,twisted handle which is multi-function used for printing two/four colors or non color, with handle or without handle.

Product instruction

This machine adopts German imported high-speed motion controller(CUP), which controls the operation of servo through high-speed bus to ensure stable movement and smooth motion curve. It is the automatic square bottom paper bag equipment with handles inline preferred by the majority of printing and packaging manufacturers. It is suitable for mass production of shopping bags in industries such as food and clothing.

Product Parameter(specification)

|

Model |

YAST-FD330TFC |

YAST-FD450TFC |

|

Cutting length |

270-530mm |

270-530mm |

|

Paper bag width |

120-330mm |

210-450mm |

|

Paper bag bottom width |

60-180mm |

90-180mm |

|

Paper thickness |

60-150g/m2 |

80-150g/m2 |

|

Production speed |

30-220pcs/min |

30-200pcs/min |

|

Paper roll width |

380-1050mm |

590-1290mm |

|

Twisted handle |

|

|

|

Cutting length |

270-430mm |

270-430mm |

|

Paper bag width |

200-300mm |

200-300mm |

|

Paper bottom width |

60-180mm |

60-180mm |

|

Paper thickness |

80-150g/m2 |

80-150g/m2 |

|

Production speed |

30-150pcs/min |

30-150pcs/min |

|

Paper roll width |

620-1050mm |

650-1290mm |

|

rope width |

12mm |

12mm |

|

rope distance |

75mm |

85mm |

|

Twisted rope height |

100mm |

100mm |

|

Rope diameter |

φ3-5mm |

φ3-5mm |

|

Patch width |

50mm |

50mm |

|

Patch length |

152mm |

152mm |

|

Patch paper roll width |

100mm |

100mm |

|

Patch paper thickness |

100-135g/m2 |

100-135g/m2 |

|

Paper bag with flat rope speed |

30-150pcs/min |

30-150pcs/min |

|

Flat handle |

|

|

|

Cutting length |

270-430mm |

270-430mm |

|

Paper bag width |

200-300mm |

240-450mm |

|

Paper bottom width |

60-180mm |

90-180mm |

|

Paper thickness |

80-150g/m2 |

80-150g/m2 |

|

Production speed |

30-150pcs/min |

30-120pcs/min |

|

Paper roll width |

620-1050mm |

650-1290mm |

|

Paper core |

∅76 |

∅76 |

|

Paper roll diameter |

∅1300 |

∅1300 |

|

Flat rope width |

12mm |

12mm |

|

Flat rope distance |

78mm |

85mm |

|

Flat rope height |

100mm |

100mm |

|

Rope diameter |

φ3-5mm |

φ3-5mm |

|

Patch width |

50mm |

50mm |

|

Patch length |

152mm |

152mm |

|

Flat rope length |

352mm |

352mm |

|

Patch feeding width |

100mm |

100mm |

|

Patch paper thickness |

120g/m2 |

120g/m2 |

|

Paper bag with flat rope speed |

30-110pcs/min |

30-110pcs/min |

|

Printing Area |

|

|

|

Printing width |

380-1050mm |

590-1290mm |

|

Printing length |

270-520mm |

270-520mm |

|

Printing speed |

10-100m/min |

10-100m/min |

|

Color accuracy |

≤±0.20mm |

≤±0.20mm |

|

Plate thickness |

2.28mm+0.38mm |

2.28mm+0.38mm |

|

Including the thickness of the double=sided current |

Customized by requirement of client |

Customized by requirement of client |

|

Working air current |

≥0.36m3/min,0.5-0.8MPA |

≥0.36m3/min,0.5-0.8MPA |

|

Power supply |

380 v 3phase 4 lines 50.5kw |

380 v 3phase 4 lines 50.5kw |

|

Machine weight |

20200kg |

20200kg |

|

Machine size |

18000*8000*2800mm |

18000*8000*2800mm |

Main features

1.Use France SCHNEIDER touch screen human-computer interface, making the machine easy to operate and control.

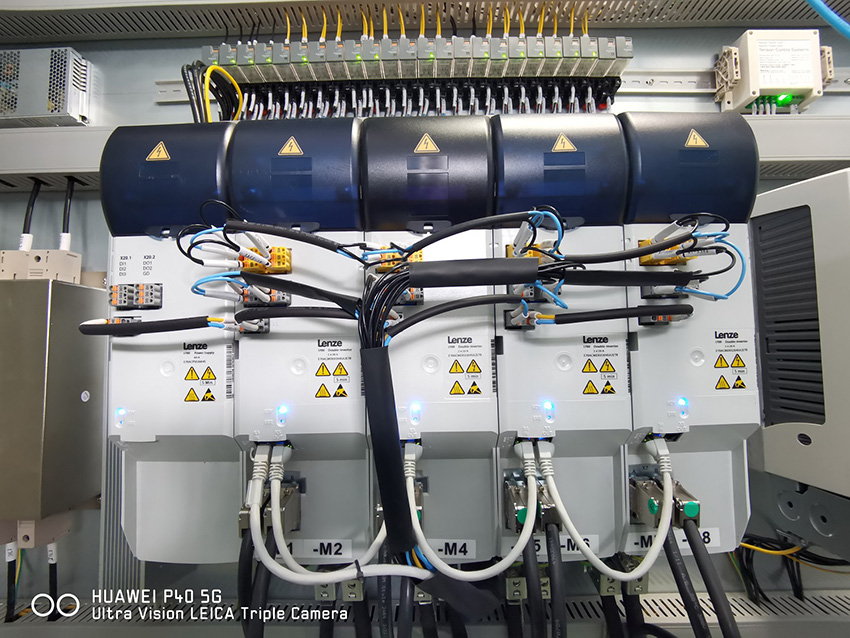

2.Adopt Germany original LENZE PC control, integrated with optical fiber. Thus ensure stable and high speed running.

3.Adopt Germany original LENZE servo motor and German original SICK photoelectric eye correction, tracking printing bag accurately.

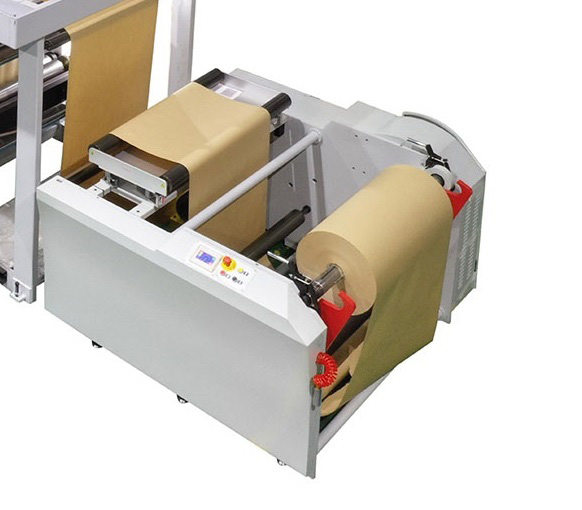

4.Raw material loading adopts hydraulic auto-lifting structure. Unwinding unit adopts auto tension control.

5.Raw material unwinding EPC adopts Italy SELECTRA, reducing material alignment time.

The flow chart

Machine details

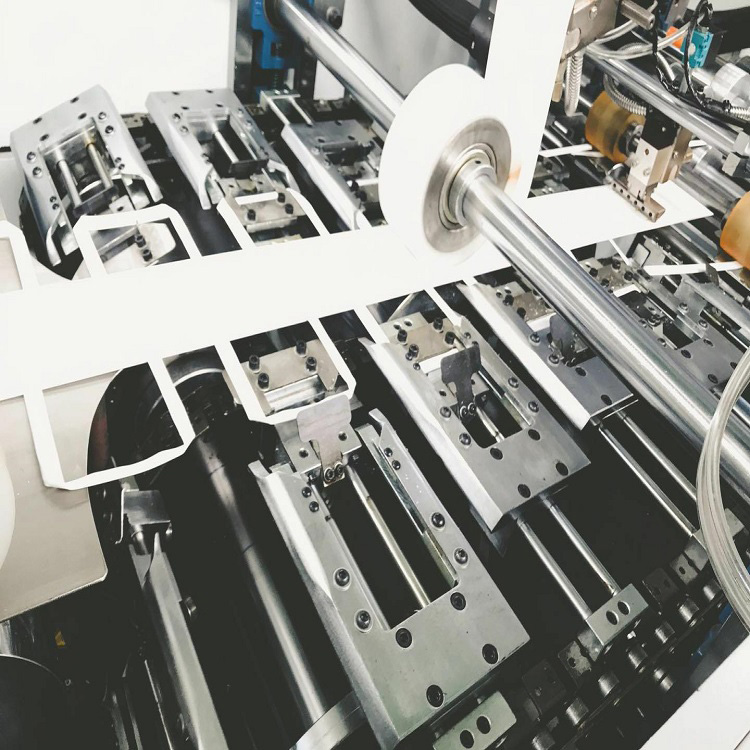

Handle making unit.

Twisted rope union,flat rope unit, The shape of the handle can be changed freely according to the demand.Servo motor control, simple operation.

1.Hydraulic automatic feeding, air expansion shaft through the paper roll, inflation to lock the paper roll to make it fixed.

2.Magnetic powder controller, tension control,constant tension control system, quick response, simple structure, high control precision, long life, stable rotation.

3.Unwinding adopts the Italian ST correction system,Make the machine at high speed when the paper will not run off,and the correction saves time and raw materials.

LENZE Servo Motor control system,for high-performance machine application in the age of industry 4.0,control parameters optimally set in 60 seconds,the hidden gem in the best control cabinets.

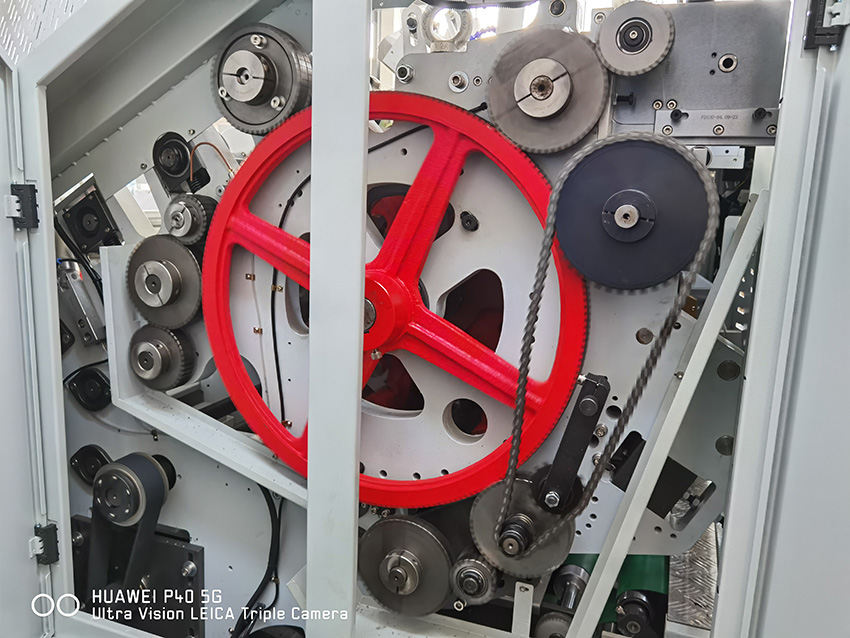

The mechanical transmission parts used in synchronous belt have high precision and good matching degree, which makes the whole machine stable and low noise, which effectively guarantees the stable high-speed operation and longevity of the equipment.

Shipping package

Deliver and serving

About 60 working days after receiving the deposit. We offer FOB price, Ningbo port. After signing of the contract ,the total amount of 30% advance payment, factory acceptance payment before delivery after the machine testing is ok.

FAQ:

Q: How to answer technical guidance?

A:For some customers who need non-standard equipment, we will communicate with the company's relevant technical personnel according to the customer's specific requirements, taking into account the technical feasibility and production costs, and give customers solutions

2.Q:How to recommend products?

A:We can also provide non-standard equipment production and new product development services according to customer requirements. According to the customer's picture of the paper bag to be produced, the purpose of the product to be purchased, the environment, the purchase volume and other related conditions, we will recommend several cost-effective products for the customer to choose.

3.Q:How to make a quotation?

A:Based on our company's research and development costs, production costs and customer purchases, we conduct calculations to determine the price of the product.

GET A QUOTE